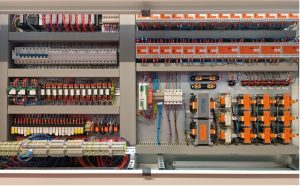

Motor control station

The client approached Rotary with the request to design and manufacture a control system to integrate several pieces of plant equipment to form a bespoke motor test facility:

- 1 Megawatt generator

- High voltage transformer & switchgear

- 300KVA Motorised transformer

- Distribution / switchgear panel

- Array of measurement devices

The solution offered allowed the client to integrate many individually complex pieces of equipment into one centralised control station where operation is managed intuitively and safely through a 21” HMI and small selection of buttons.

After successfully operating the test facility for several months, the client requested additional temperature monitoring capability. Rotary were able to swiftly produce an add on control panel and integrate it seamlessly into the HMI’s user interface.

Rotary has subsequently worked with this client on further projects, including the design and manufacture a turnkey motor test facility which has been rolled out in multiple locations internationally.

Motor test facility

An international Company recognised a need to upgrade and automate their motor test systems. The client approached Rotary to supply new motor test facilities to match their exact criteria.

Rotary worked alongside the customer to produce a specification which both met and exceeded the original criteria. Subsequently we developed, manufactured, and commissioned a turnkey motor test panel which allowed the customer to safely test AC/DC motors up to 750KW remotely from a control station with 21” HMI.

The system functions by gradually ramping up voltage to a test motor whilst recording electrical and mechanical parameters such as speed, current, power factor, vibration, and temperature. All test data is displayed on a 21” HMI with the ability to export as a .CSV file. Automatic test sequences were incorporated as well as a state-of-the-art motor drive.

The new test facility is now being rolled out to multiple branches in the UK and overseas.

Brewery cask washer

A brewery approached Rotary to upgrade and update their cask washer process. Rotary assessed the application and implemented both electrical and mechanical upgrades to their current process. This consisted of installing new pneumatic actuators and controls which were responsible for handling the casks as well as a new PLC/HMI based control system for sensing and managing the process.

Rotary handled the whole project from concept to commissioning.

Key aspects: Software, PLC, pneumatic, water, position, Sequence control, Liquid, sensors.

Control Panels for OEMs

A leading UK OEM was facing increased demand for PLC Touch screen controls on their equipment in preference to their push button system, but had no in-house capability to develop such a system. They approached Rotary to supply new PLC driven touch screen controlled operating system for their equipment. Rotary Automation worked with the client to establish all the key parameters, then designed and delivered an operating system that covered all the control parameters and offered much more functionality including live current process data, data logging, and programmable sequence control.

The project included control of temperature, water, and air along with emergency shut down procedures and safety controls. Data logging, and remote engineering level access are also available as an option. Engineering level access allows the client to test individual systems for commissioning the equipment giving them complete control of the system.

Rotary Automation now supplies the control system for our client to integrate into their machines.

Heavy Duty Heat Press

The client approached Rotary Automation to fully upgrade and update their existing machine, originally manufactured in Europe.

Rotary designed, installed and commissioned a PLC driven solution which is controlled through a touch screen interface.

The system update consisted of designing and manufacturing electrically powered heater bars to replace the existing steam powered bars, replacing the hydraulic power pack and producing an intelligent control system to manage and monitor the process. The resulting system allowed the operator to accurately configure, store and run complex pressing procedures (heat, time, pressure) to achieve an optimum product. Data throughout the procedure can be viewed in real time and exported for quality records.

Rotary handled the whole project from concept to commissioning and went on to roll out similar packages across the range of customers equipment.

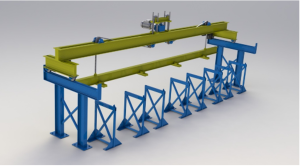

Pick and Place

This customer required an automated magnetic handling solution to lift up to 6.2 meter lengths of steel from a stack onto a guillotine. The design had to fit within the existing footprint, integrate with the guillotine and be able to pick up metal bars singularly from a stack.

Rotary Automation worked with the customer to establish the key performance criteria before designing an automation system to deliver the requirements.

PLC control and motor and inverter drives were used to accelerate and decelerate the process. In addition, advance programming ensured that the magnetic strength varied to match the load to prevent picking up two pieces of steel accidently. The control system incorporated reverse polarity pulse to improve the magnetic release and ensure the magnet and material being handled did not build up residual magnetism.

On this occasion Rotary Automation worked hand in hand with the parent company Rotary Engineering who designed and supplied the mechanical parts of the system.

Plate Glass Manufacturer

The client approached Rotary Automation to resolve a problem with build up of molten glass and sulphur particles on process rollers in their float glass plant without stopping the continuous glass-making process. An automated system was designed to drop individual rollers, process the rollers by cleaning off the residue, and re-instate the clean rollers. The solution had to be able to work in high temperatures and handle hot rollers.

The solution incorporated PLC control and inverter drives to manage the feed rates, pressure and cleaning cycle. Rotary handled the whole project from concept to commissioning.

+44 (0) 114 251 3134

+44 (0) 114 251 3134